Cutting edge engineering solutions that support the iron and steel industry

Tenova‘s multidisciplinary team of specialists have extensive industry knowledge to focus on what is important to you, our customer. Whether your need is to address a current deficiency or to reach a long term future goal, our fume system capabilities can support and improve your plant in the following areas:

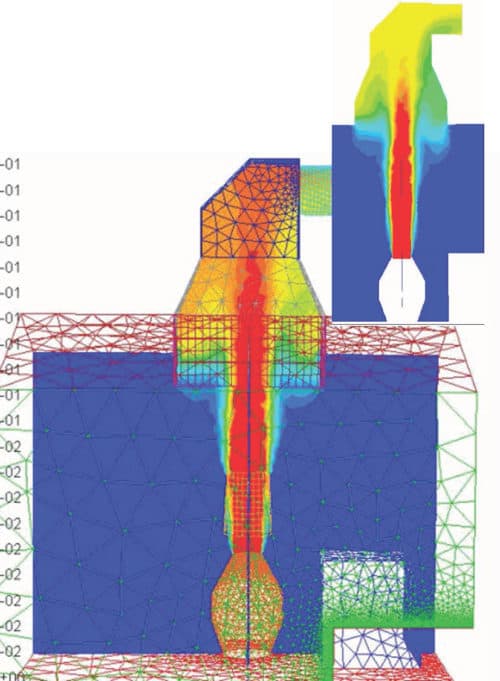

- Primary System Exhaust Capacity Issues

Reduced exhaust capacity, fugitive emissions during melting/refining operations, potential for elevated CO levels, draft controls and used energy optimization - Primary System High Temperature

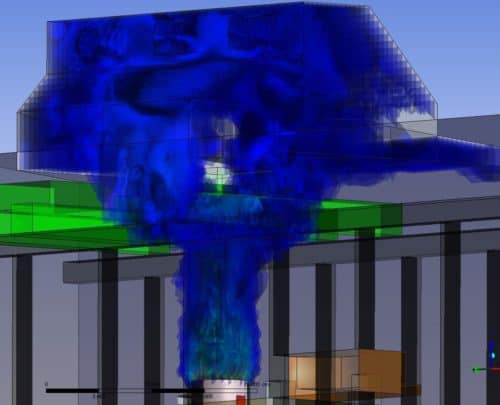

Increased off-gas energy loss, EAF over-draft capacity, poor combustion chamber design, poor primary system mixing efficiency and low heat transfer efficiency - Poor Canopy Hood Capture Efficiency

Shallow design-fume bounce out, no fume storage capacity, lack of dedicated exhaust, no internal recirculation flow pattern - High Temperature in Baghouse

Inadequate canopy hood geometry, exhaust capacity, capture and evacuation efficiency - Melt shop Ventilation (Heat and Emissions)

Poor melt shop indoor air quality, visibility and potential for elevated CO levels

A better process performance can be achieved through one of the following formats:

- Process studies and assessments, including system performance analysis

- Conceptual designs, including economic feasibility and assessments

- Basic and detail design for competitive contractor bidding

- Commissioning, tune-up and start-up services, including performance testing

Contact Tenova Goodfellow Inc., today to speak to our qualified fume system representatives and to request a quote.

Checkout Our Ebook Library

View Ebooks