OTM – Optical Temperature Measurement

Tenova Goodfellow Releases High-Intensity Industrial Gas Stream Temperature Measurement

In industries where it is vital to get an accurate temperature reading of a process’ gas, dust and particulate debris can get in the way.

Obtaining an accurate and consistent read on gas like this can be difficult. Thermal sensors mounted in thermal wells can be damaged in these conditions.

In a thermal well design, a delayed measurement can result due to temperature changes being absorbed by the well material.

Tenova Goodfellow has released a new gas velocity sensor to make a continuous, accurate read of dusty, hot gas streams possible.

Now, users can measure the temperature to an accurate degree, even for gases in excess of 750° C. Many other methods meant to measure temperature and velocity of dusty, hot gas streams would not survive the harsh environment. For example, an electric arc furnace is a chemically aggressive, dusty and hot environment in which a reading would normally be very difficult.

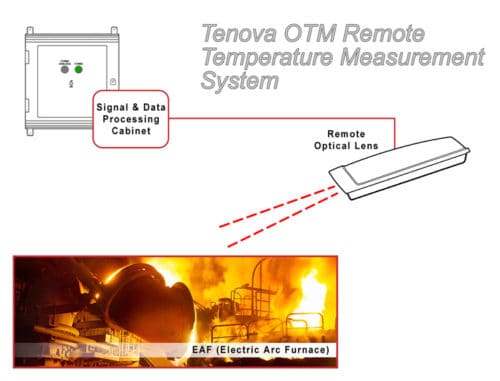

The OTM system is a rugged, stand alone, non-contact thermometer designed for measuring the temperature of hot gases. The system utilizes a two color pyrometric technique to measure the temperature of hot gases with a temperature measurement range of 500 to 2500oC or 1112 to 4532oF. It can be used for any kind of hot gases and is not dependent on the presence of CO2. Therefore it can be applied to a variety of applications. It does not need any future calibrations.

Some industries that may require this type of measurement include cement making, steel-making, petroleum refining and chemical production, as well as metallurgical smelting and power generation.

Using a non-contact passive sensor, the Tenova Goodfellow Gas Temperature Measurement system has no consumable parts and rarely requires maintenance.

The sensor consists of one optical remote lens mounted up to 30m away from the target, optical fibers, and a sensor cabinet. Alternatively, the lens may be mounted at the process duct using a direct-mount assembly.

A nitrogen purge system is also available for the direct-mount option. The sensor cabinet contains the optical sensors and industrial processor. It is a NEMA 4 climate controlled cabinet suitable for indoor / outdoor mounting.

Based in Canada, Tenova Goodfellow supplies advanced technologies, services and products worldwide the metal industries. Process automation and metallurgical expertise drives us to deliver innovative solutions to our valued customers. Contact us for gas temperature measurement in dusty, hot applications.