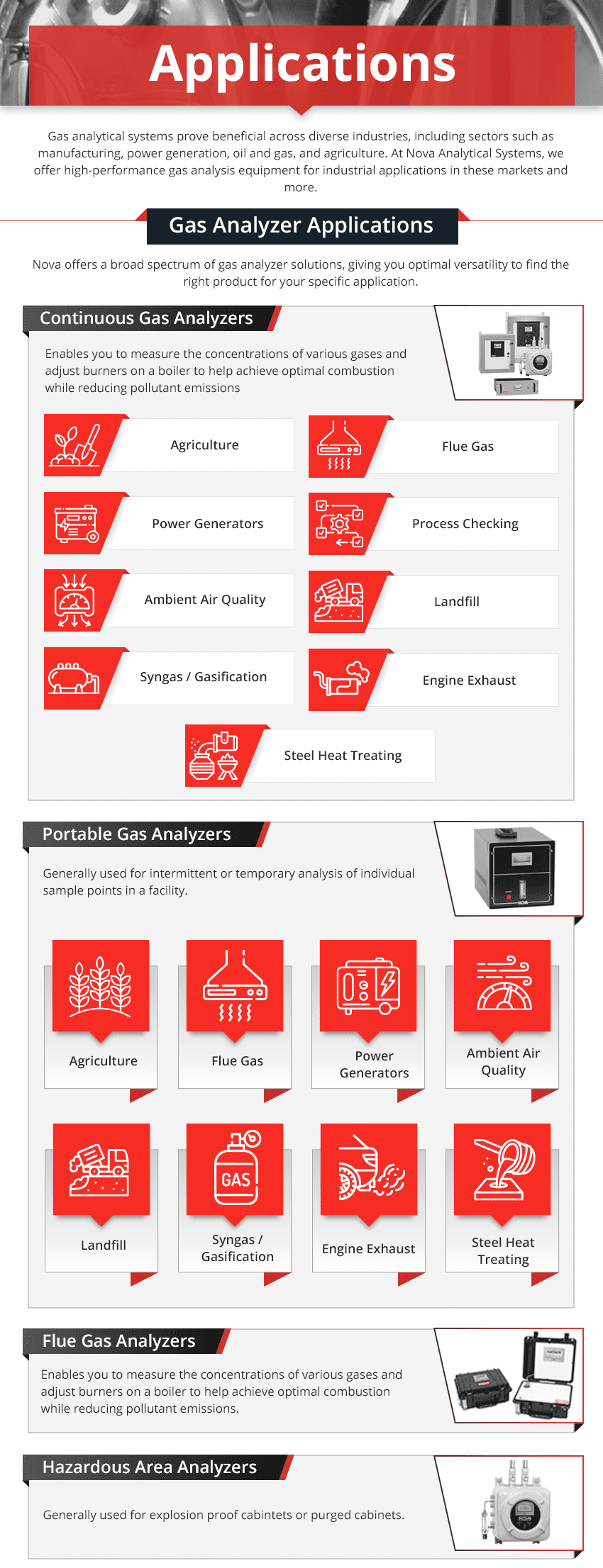

Nova offers a broad spectrum of gas analyzer solutions, giving you optimal versatility to find the right product for your specific application.

Continuous Gas Analyzers

Continuous gas analyzers are among Nova’s core competencies. We carry a wide selection for various industrial applications that require ongoing analysis of gas samples from one specific area or process in your facility. Utilizing permanent mountings for installation on walls or vertical surfaces, these instruments are typically larger than portable varieties, and contain the components necessary for continuous use.

Portable Gas Analyzers

Another large part of our product line, portable gas analyzers allow for temporary or occasional analysis of distinct sample points within your facility. These products are usually available in suitcase, or bench-top style cabinets. While this equipment isn’t ideal for long-term gas analysis given their small size for optimal portability, these analyzers are a perfect choice for tuning and spot-check tasks.

Flue Gas Analyzers

By burning fuel with oxygen present, equipment like heaters, boilers, and furnaces effectively generate heat. Balancing air and fuel allows for high efficiency in the combustion process, with a side benefit of savings on energy costs. The purpose of a flue gas analyzer is to measure varying gas concentrations so that you can make adjustments to your heating equipment, obtaining the proper combustion level while reducing pollutant emissions.

Hazardous Area Analyzers

Nova develops analyzers in cabinets that are applicable for Class 1 Divisions 1 and 2 and Zone 1 or 2 Hazardous Areas. Our explosion-proof cabinets consist of heavy-cast aluminum, and the analyzer’s gas entry and exit points have flame/flash arrestors, and EYS seals for the wire entries. Due to internal cabinet space limitations, analyzers in hazardous areas often only measure one type of gas within a dry, clean sample. If you need to analyze multiple gases, larger analyzers with positive-pressure purge systems may also be available for use in hazardous areas.

Heat-Treating and Metal-Finishing Analyzers

In heat-treating furnaces and metal-finishing processes for steel mills and related operations, gas analyzers provide an optimal solution for monitoring flue and atmospheric gases. The analyzers help evaluate if the furnace atmosphere is suitable, if any fuel is burning efficiently, or if the air around the furnace is safe.

Landfill & Bio-Gas Analyzers

The gas you find in landfills is similar to that found in biogas applications because the chemistry of the processes are basically the same. In these applications, gas analyzers are typically used to evaluate the energy content and some of the contaminant contents of the produced gas. These measurements will help inform the operator if the gas is suitable for use as an energy source, or possibly if burning the gas has some carbon credit value.

Portable Engine Exhaust Analyzers

These portable analyzers from Nova evaluate the gas that combustion engines produce, accurately measuring the following:

- Oxygen (O2)

- Carbon Monoxide (CO)

- Carbon Dioxide (CO2)

- Nitrogen Oxide (NO)

- Nitrogen Dioxide (NO2)

- Hydrocarbons (HCs)

Understanding the exhaust gas composition will help a mechanic to evaluate engine performance and efficiency.

Power Generation and Hydrogen Purity Analyzers

Nova’s power generation and hydrogen purity analyzers provide accurate, reliable hydrogen analysis, backed by our extensive history of offering gas evaluation products to the power generation sector. Maintaining hydrogen purity supports operational efficiency and long-term, maximal functionality in your generator’s components. As hydrogen applications in the power generation market are typically uniform, we have developed standardized analyzers for high-quality gas analysis for this industry.

Process Gas Analyzers

Gas analyzers for low-intensity process applications can sometimes utilize simplified lighter-duty designs. Minimizing the sample conditioning systems is sometimes possible when the sample gases are dry and clean. When the pressure and other conditions of the process allow it, the analyzed gas might also be returned back into the process.

Steel-Making Analyzers

Gas analyzers provide an optimal solution for monitoring flue and atmosphere gases in heavy industrial sectors like steel mill operations. Oxygen and electric arc furnaces generate steel from scrap material, iron ore, or direct reduced iron products. Steel-making analyzers can handle high temperatures and effectively optimize both the post-combustion and chemical energy in furnace processes.

Syngas Analyzers

A byproduct of the pyrolysis process, syngas has energy value for use in applications such as boilers, turbines, gas engines, steam cycles, etc. The energy production and chemical processes that use gasifier-derived gases as an energy source rely on analyzers to ensure that the syngas has the proper chemical and energy content before it is used in the intended application.

Other Energy-Intensive and Remote Location Analyzers

Installing a gas analyzer outdoors or in a remote location can mean subjecting the analyzer to challenging conditions and reduced maintenance efficiency. High-energy projects often generate high temperatures and pressures, dust, moisture, and other conditions that may threaten an analyzer’s performance. Tough, high-functioning equipment is needed for these kinds of specialized applications.