Power Generation and Hydrogen Purity

Nova has a long history of providing gas analysis to the power generation industry. This mainly because of our capability for hydrogen analysis.

Nova 436 Series Continuous Tri-Gas Analyzers

Nova 380K Series Portable Tri-Gas Analyzers

Power Generation Analyzer Catalog

Description

Hydrogen applications in the power industry tend to be fairly uniform which allows for the development of high quality and standardized gas analysis solutions. The best example of this has to do with the gas atmosphere that exists inside of many large stationary electric power generators.

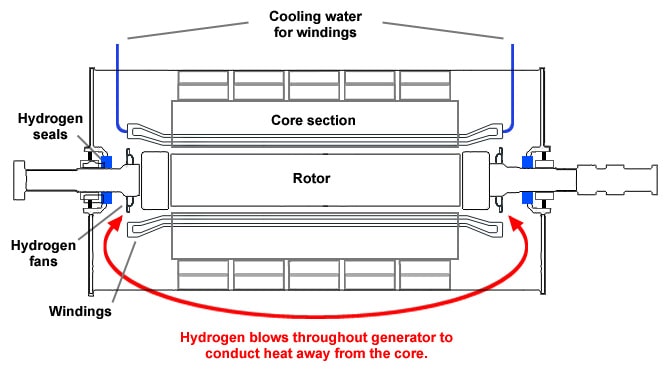

As current flows through a conductor, heat is generated. By the same principle, the currents flowing through the windings of an electric power generator produce a large amount of heat. Heat build-up can cause insulators and conductors to deform and elongate which may damage the generator. Even if no damage occurs, there will be a loss of efficiency because heat-related effects will place limits on the amount of electrical power that can flow through the generator.

In order to control these losses and keep efficiencies high, the hydrogen purity must be maintained. Even a slight contamination of the hydrogen by oil vapor, water, or air will increase the windage losses in the generator. For example, a 1% reduction in hydrogen purity creates a 12% increase in windage loss. A decrease in purity from 99% to 92% can reduce generator output by as much as 2100 kW. Obviously, this reduction in generator efficiency results in higher fuel costs and replacement power requirements.

It is possible to flow air into and through a generator to carry away the excess heat. However, most power generating plants use hydrogen (H2) gas to cool the electrical windings within the turbine generators. Hydrogen has a much higher thermal-conductivity value than air. It is much better at conducting heat than air is. For example, if we give a thermal-conductivity value of 1.00 to air at 100C, H2 will have a corresponding thermal-conductivity value of 6.80. Flowing H2 gas into a generator will therefore remove more heat from the windings of the generator. The H2 flows in a closed loop through the generator and into a heat exchanger.

The main challenge with using H2 as a cooling medium is that it is explosive when mixed with air and exposed to an ignition source. The only way to avoid this is to maintain a high level of H2 purity in the generator, thus excluding air. The H2 will not explode in the absence of air even if an ignition source is available.

Purge Procedure

To perform maintenance work in the generator enclosure, the H2 must be purged out with CO2 (carbon dioxide) gas. The CO2 must then be purged out with breathable air. When the maintenance work is complete, the same purge procedure is performed, but in reverse.

The best way to monitor the gases in a generator is to use a gas analyzer system with the following ranges:

Generator Purity Mode

- Range 1: 0 – 100.0 % H2 in Air

Generator Purge Mode

- Range 2: 0-100% H2 in CO2

- Range 3: 0-100% Air in CO2

To perform maintenance work in the generator enclosure, the H2 must be purged out with CO2 (carbon dioxide) gas. The CO2 must then be purged out with breathable air. When the maintenance work is complete, the same purge procedure is performed, but in reverse.

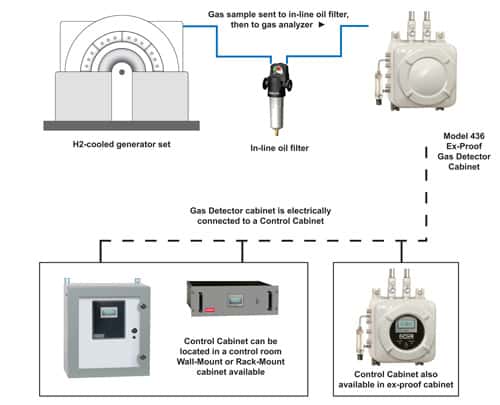

The Nova Model 436 Series Tri-Gas Analyzer is designed specifically for monitoring hydrogen purity in the hydrogen feed to a power generator and to monitor the purging procedure during shut down.

The analyzer can measure the following gases by switch selection:

- Range 1: 0-100.0% Hydrogen in Air

- Range 2: 0-100.0% Hydrogen in CO2

- Range 3: 0-100.0% Air in CO2

Models 436RMN7 and 436N4N7 analyzers have two components:

The control section contains the main microprocessor board as well as the digital readout meters, alarms, calibration and range switches, power supply and temperature controller for the T/C cell. (The control section is also available in a grey NEMA4 cabinet.)

Nova 436 Series Control Cabinet – choice of

Rack Mount or Wall Mount styles

The gas detector section contains the temperature controlled thermal conductivity cell, a five way selector valve, gas pressure regulator, flow indicator and 2 flame arrestors.

Nova 436 Series Ex-Proof Detector Cabinet [on left]

- The gas detector cabinet is UL listed and CSA certified for use in Class 1 Division 1 Groups BCD hazardous areas. The control cabinet is for use in a general purpose, non-hazardous area.

- A 4-20 mA output and two alarms are provided for the range of 85-100% hydrogen in air.

- Here’s the catalog link to the 436 Series

If you are a power plant operator and you need a quote for this instrument, you can request a quote or view our catalog of products.

Portable Analyzers for Power Generators

Many generator facilities have continuous analyzers permanently mounted on/near each generator set. However, it is also desirable to have portable tri-gas analyzers as a back-up. The portable instruments are much smaller in size and have fewer features. The continuous and portable analyzers share the same analysis principles and ranges.

380K Series

The Nova 380K Series is a portable tri-gas analyzer suitable for hydrogen purity and purge monitoring. It is used world-wide by many power generation companies and facilities. It has built-in switch-selectable digital display, sample pump, regulator, flow control assembly, liquid block, filter and flow meter.

Other Information on the 380K Series

- We have a detailed page with more information about this instrument .

- Here’s the catalog link to the 380 Series.

- See this Nova blog post to read about the simple calibration procedure for this instrument.

- Here is a short Nova YouTube video that shows this instrument in operation.

- If you are a power plant operator and you need a quote for this instrument, you can request a quote here or view our catalog of products here.

- This page is primarily about hydrogen purity analysis for power generators. If you are interested in hydrogen analysis for other applications, see this page.

- To provide us with more information about your application, please complete our Application Questionnaire and our Sales team will follow up with you promptly.