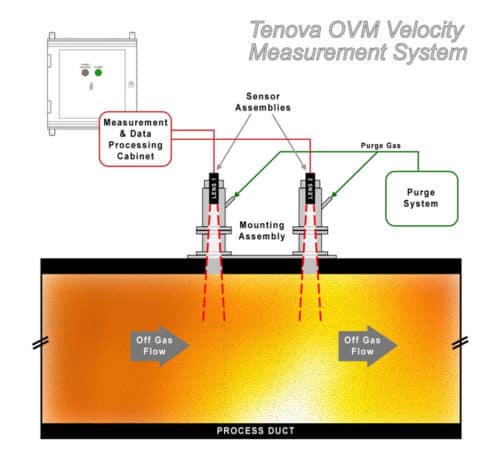

OVM – Optical Velocity Measurement

Tenova Goodfellow Introduces Velocity Measurement for High-Intensity Industrial Gas Streams

The velocity of a gas as it exits a process is vital information in some industries. A relatively simple measurement, it can pose a problem when the process emits dust- and particle-filled gas that’s very hot.

Consistently and accurately measuring the velocity of the gas can be quite challenging.

Steelmakers and cement-makers are just two industry examples that potentially measure this type of gas stream, as well as petroleum refiners, chemical producers, metallurgical smelters and power generators.

For example, in steelmaking, fast and accurate readings are key to an optimized process. In the making of steel, oxygen gets blown into molten steel to react with carbon, forming carbon monoxide and carbon dioxide.

This residual carbon content is important to the final product, and so is an accurate reading of this and the velocity and temperature.

With Tenova Goodfellow’s new gas velocity sensor, a continuous measure of velocity is possible in a dusty, hot gas stream.

Now, industry workers affected by this problem can measure the velocity of gases at 750° C or hotter, and do so with a high degree of accuracy.

This saves them from inaccuracies that other velocity measurement methods produce, if the device survives the harsh environment at all.

A non-contact passive sensor with zero consumable parts is the crux of the Tenova Goodfellow Gas Velocity

Measurement system, which also offers a relatively maintenance-free requires minimal maintenance. The system measures gas streams from zero to 60 m/s (meters per second).

For more information about this product or any other Nova Analytical Systems’ product, contact us today.