What Is Anaerobic Digestion?

Organic material refers to carbon-based compounds formed by living organisms (e.g., animal manure, food waste, and wastewater biosolids). It can be turned into more usable compounds (i.e., biogas and digestate) through a process known as anaerobic digestion.

The anaerobic digestion process utilizes microorganisms to break down organic material in the absence of oxygen. It occurs within a sealed vessel called a reactor or digester, which contains microbes that process (i.e., digest) the material and produce biogas and digestate. These end products are then discharged from the vessel so they can be collected and used.

Checkout Our Ebook Library

View Ebooks

What Does an Anaerobic Digester Produce?

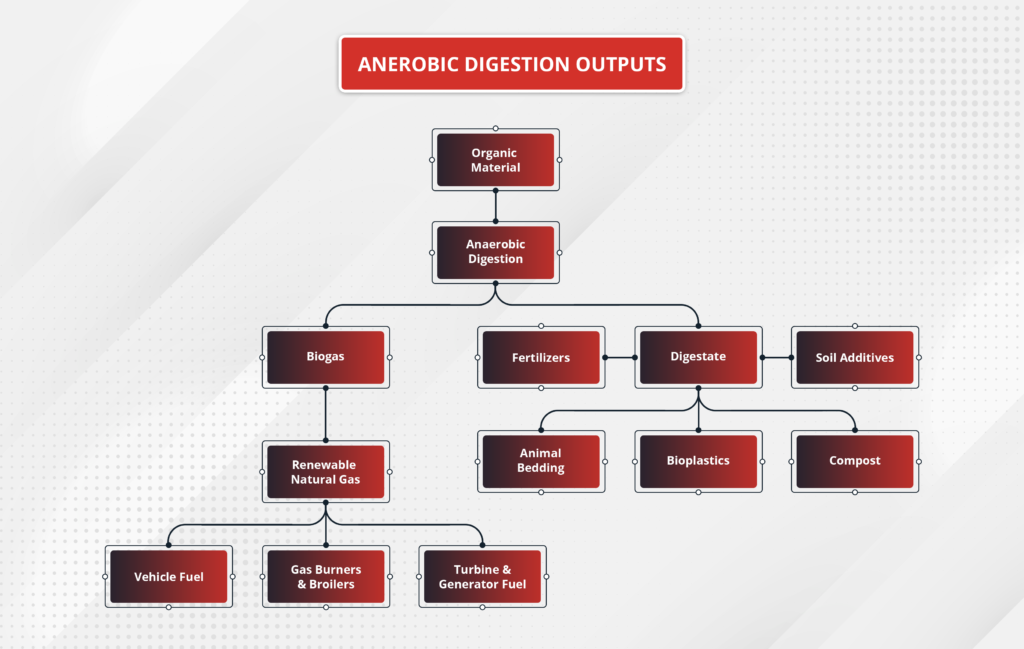

The process of anaerobic digestion produces two key products: biogas and digestate.

Biogas

Biogas consists of methane, carbon dioxide, hydrogen sulfide, water vapor, and trace amounts of other gaseous compounds. Several types of bacteria are involved in producing it. First, first-stage bacteria break down the carbohydrates present in the material into soluble compounds (e.g., sugars and amino acids. Next, acidogenic bacteria consume these compounds and convert them into ammonia, carbon dioxide, hydrogen, and organic acids. Then, these compounds are turned into acetic acid, which is converted into biogas by anaerobic methanogenic archaea bacteria. Finally, the biogas can be purified to generate renewable natural gas (RNG). This final product can be used as a power source for various equipment.

Digestate

Digestate is the material remaining after anaerobic digestion. It consists of solid and liquid components, which are generally separated and handled individually since they can be valuable with proper post-processing. Applications include animal bedding, bioplastics, compost, fertilizer, and soil additives.

Types of Anaerobic Digesters

There are many types of anaerobic digesters available. They can be classified into four general categories:

- Covered anaerobic lagoon digesters: These systems are sealed with a flexible cover. They are designed to recover and pipe methane to the combustion chamber.

- Plug flow digesters: These systems feature a low, narrow concrete tank with a rigid or flexible cover. They are designed to be partially or fully below grade, which limits the demand for supplemental heat.

- Complete mix digester: These systems have an enclosed and heated tank with a mechanical, hydraulic, or pneumatic mixing mechanism.

- Dry digesters: These systems have an upright, silo-style design. They are made from concrete and steel and feature a rigid cover.

Anaerobic Digesters From Nova Analytical Systems

Anaerobic digestion primarily produces carbon dioxide and methane. However, trace amounts of other gases, such as hydrogen sulfide, nitrogen, and oxygen, are also generated. While these compounds can be valuable when properly handled, they can also present some problems, especially methane. Methane greenhouse gas is 20 times more potent than CO2. That’s why many countries require gas levels to be monitored at biogas and landfill sites. Facilities may also integrate an analyzer system between the gas supply line’s output and the receiving process’s input to determine the specific makeup of the gas, which is essential to attaining and maintaining efficient and safe operating conditions. Different gas readings can be used for different purposes. For example, oxygen readings can be used to detect inbound air leaks in the collection system, while carbon monoxide readings can be used to detect subsurface fires.

Need gas analyzers for your biogas or landfill facility? Nova Analytical has got you covered! We offer a variety of gas analyzers systems to suit different customer applications. To learn more about our product offerings and how they can benefit your facility, contact us or request a quote today.

Comments are closed