About Tenova Goodfellow

Tenova SpA, based in Castellanza, Italy, is a world-wide supplier of advanced technologies, products and services for the metal and mining industries providing innovative integrated solutions.

Tenova Goodfellow Inc. (TGI) is a Canadian incorporated company that offers world class process control technology and fume system engineering design services along with state-of-the-art off-gas analysis equipment and novel sensors. As one complete package, TGI remains a world leader and a “Centre of Excellence” for process control technology development within the Tenova Group of Companies.

Technological innovation is the main pillar of TGI’s competitive strategy which is focused on delivering innovative and integrated Clean tech solutions that will improve the energy efficiency of our customers. Providing clean process control technology to combustion intensive industries such as steel and cement, TGI has been able to achieve dramatic reductions in energy consumption and GHG emissions associated with these industries.

Our expertise can be found in our brands that are well known on a global scale:

i EAF®: Benefits of the Intelligent EAF model include lower conversion costs, increased productivity, improvements in steel quality, environmental benefits and improved safety. Off-gas composition measurements are utilized to ascertain important information such as resolving mass and energy balance of the gas phase, bath/slag for EAF.

EAF®: Benefits of the Intelligent EAF model include lower conversion costs, increased productivity, improvements in steel quality, environmental benefits and improved safety. Off-gas composition measurements are utilized to ascertain important information such as resolving mass and energy balance of the gas phase, bath/slag for EAF.

⇒ Dynamic Chemical Energy Control & Optimization module for optimization of burners, lances and injectors. Optimized practice with a proven closed loop control methodology fully integrated with the plant automation system

⇒ Dynamic Melting Control module for off-gas temperature/ pressure/flow rate measurements. Novel sensors are combined with real time mathematical models for mass energy balance help to pace the EAF operations based on melting percentage.

⇒ Dynamic End-Point Control module monitors and evaluates the refining process using various scenarios. The module uses data from novel sensors combined with bath & slag process control modules to optimize the refining path and determine end-point conditions.

iBOF®: Breakthrough technology designed to reduce operating costs by lowering tap alloy additions, refractory consumption and oxygen use; increasing yield, productivity and scrap-melting capability and reducing GHG emissions.

iBOF®: Breakthrough technology designed to reduce operating costs by lowering tap alloy additions, refractory consumption and oxygen use; increasing yield, productivity and scrap-melting capability and reducing GHG emissions.

⇒ End-point Detection module is industry proven for measuring temperature, flow and pressure. BOF process control models enable “Blow & Tap” practice without additional cost for prediction of slag & bath chemistry, temperature from start of blowing.

⇒ Intelligent Slopping Detection System (iSDS®) uses lance vibration analysis with real-time alerts to provide advance warning of the onset of a slop and a measurement of slop severity. Provides feedback for rapid mitigation of slopping events.

⇒ Optimized Post-Combustion provides independent control of primary and secondary oxygen to control secondary oxygen flow-rate, penetration and timing, resulting in optimal efficiency and scrap-melting capability with minimal refractory or lance wear.

⇒ Automatic Tapping Control employs advanced image analysis together with process models to control tapping practice, in either an operator-assist mode or a fully automatic mode. Decreases tap time and variability and reduces slag carry-over.

NextGen®: A hybrid laser/extractive off-gas analysis technology using a single compact optical analyzer to continuously analyze off-gas from multiple off-gas sampling locations. The NextGen® system offers fast response time to provide effective dynamic control as well as:

⇒ Provide full spectrum off-gas analysis CO, CO2, O2, H2 and H2O vapor⇒ Incorporate a single “multi-point central optical analyzer for continuous analysis & reduced hardware costs especially for systems requiring multiple off-gas sampling points

⇒ Be configured for dynamic control of fume system suction

⇒ Reduce installation and maintenance costs

⇒ Be configured to provide the most comprehensive off-gas based Water Detection technology

⇒ Provide system reliability from start to end of heat, with no interrupted laser transmission

Water Detection Technology® (WDT): is specifically tailored to the furnace dimension, cooling flow-rate, charge scrap and operating requirements. It is the only technology worldwide capable of detecting both H2O and H2. While not a certified safety device, WDT significantly enhances EAF safety and is self-adapting to changes in process conditions, including ambient weather fluctuations and varying scrap conditions.

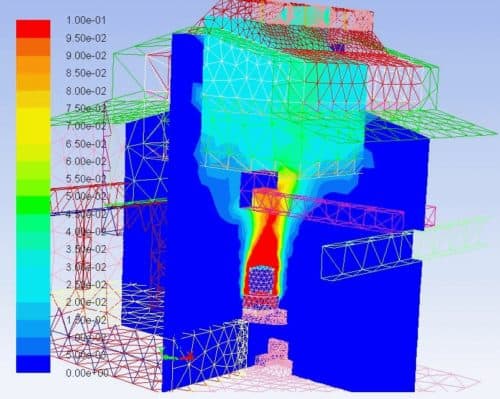

Fume System Control: include full consulting and engineering solutions to address all aspects of fume system control & optimization, process performance and related equipment design. Capabilities consist of: feasibility study for new and existing fume control performance assessment and troubleshooting; Computational Fluid Dynamics (CFD) Modeling to evaluate performance and cost effectiveness strategies for all related equipment and processes; services for EAF optimization and improved energy efficiencies

For world class, innovative technologies and engineering services for steel, contact Tenova Goodfellow Inc.

Visit Tenova Goodfellow on the web at:

Tenova Goodfellow Inc.

10 Kingsbridge Garden Circle, Suite 601

Mississauga, ON L5R 3K6 CANADA

Tel: +1 905 507-3330

goodfellow.ca@tenova.com