What Do Continuous Gas Analyzers Do?

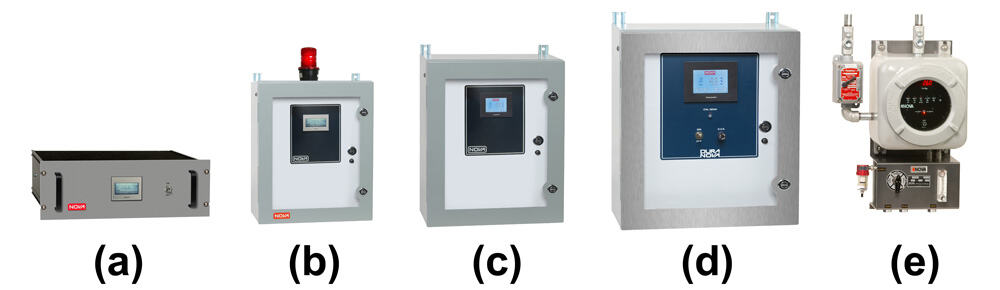

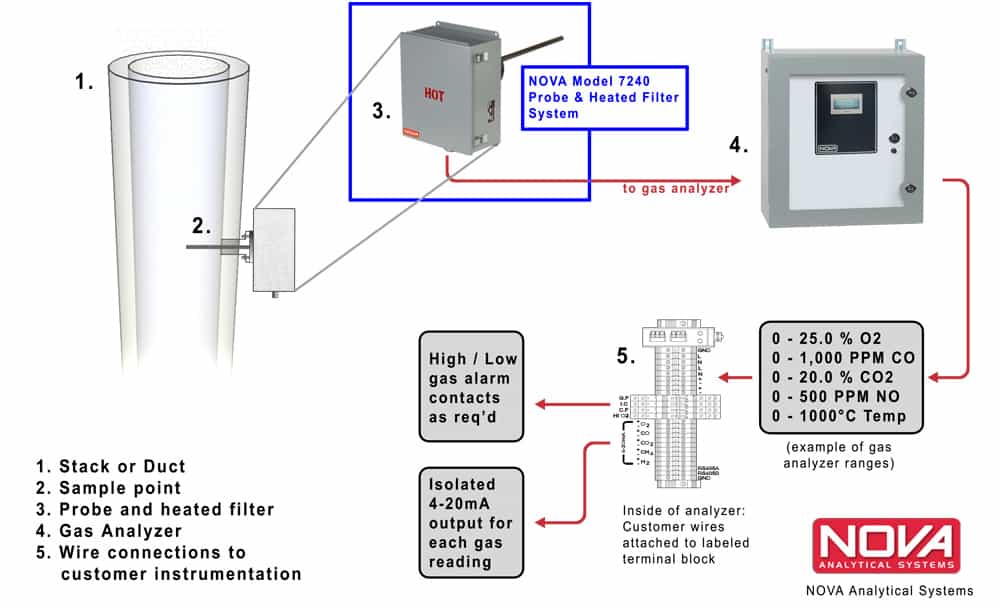

Continuous gas analyzers are generally designed to monitor the levels of one or more designated gases at individual sample points within a facility. These are usually cabinet-sized systems that are permanently installed and are larger and have more capacity than portable gas analyzers. Since these analyzers undergo continuous exposure to a sample gas, they often incorporate sample conditioning equipment to clean or dry the sample gas before analysis.

Real-world applications of these systems include hydrogen plants, landfills, steel mills, and other facilities where process gas data is required in order to ensure safe and efficient operations. Common industrial applications for Nova gas analyzers include:

- Biogas production.

- Combustion efficiency.

- Flue gas monitoring.

- Hydrogen purity.

- Power generation.

- Steelmaking.

Gases Measured

Continuous gas analyzers may be suitable for monitoring many different gases. Some are used to only monitor one gas in a mixture. Nova’s gases measurement capabilities include:

- O₂: Oxygen.

- CO: Carbon monoxide.

- CO₂: Carbon dioxide.

- CH₄: Methane.

- H₂: Hydrogen.

- SO₂: Sulfur dioxide.

- NO: Nitric oxide.

- NO₂: Nitrogen dioxide.