Landfill Gas Analyzers & Biogas Analyzers

Nova 910 Series Continuous Landfill Gas Analyzers

Nova 920 Series Continuous Biogas Analyzers

Landfill and Biogas Analyzer Catalog

Discussion

Analytical industry terminology frequently separates biogas and landfill applications into two different categories even though the gas itself is similar. Landfill sites have diversified waste input streams which seem to have an averaging effect on the gas composition from site to site.

The gas can be quite aggressive and corrosive. But from a gas analyzer perspective, landfill applications are generally predictable and consistent enough to allow standard analytical equipment to be specified.

Biogas applications may have gas that is produced from uniform feedstocks utilizing specific plant designs. For example, a palm oil facility will likely have only agricultural waste originating from a palm oil plantation. This means that the produced gas may be more characterized. It is therefore wise to obtain an analysis of gas composition and conditions before specifying permanent analytical equipment. Biogas applications also frequently have multiple sample points or other requirements that need to be addressed.

Gas Production

Biogas results from the metabolic activity of microorganisms on organic matter. Landfill gas is a type of biogas that originates from the decomposition of organic waste in a landfill. Biogas production is not isolated to landfill waste only. Any organic waste may be decomposed in the absence of oxygen to produce biogas. Agricultural waste and the effluent from wastewater treatment plants are frequently utilized as sources of biogas.

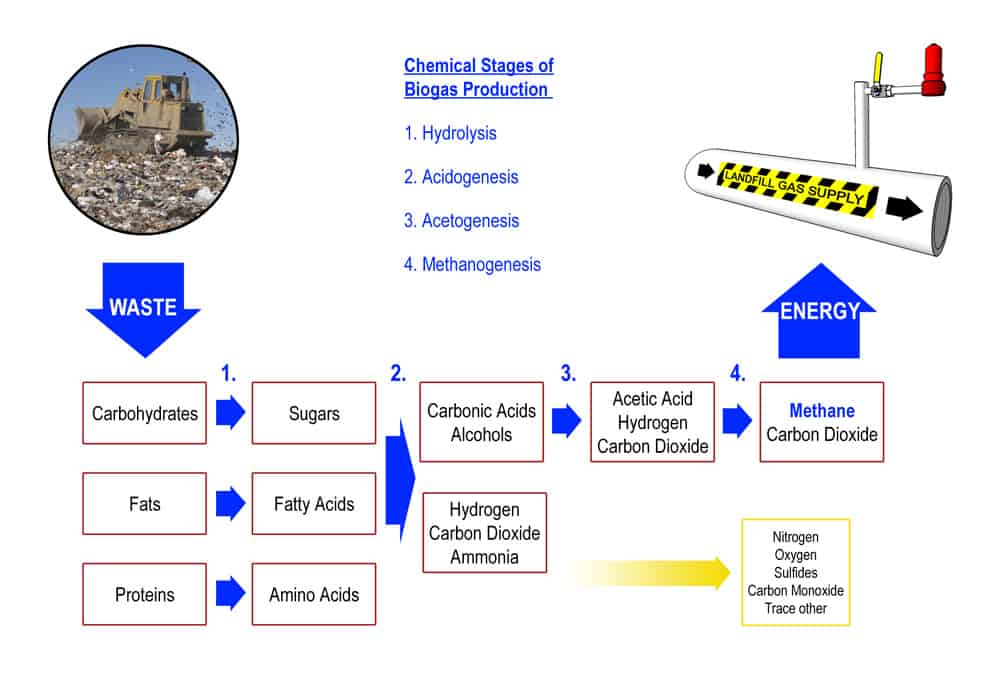

This process, called anaerobic digestion, produces primarily methane and carbon dioxide. Several other gases are also produced such as nitrogen, oxygen, hydrogen sulfide and others. Anaerobic digestion is a multi-stage process comprised of different microbes and chemical reactions.

Bacterial hydrolysis starts the biogas production process by breaking down insoluble components such as carbohydrates and fats to produce sugars and amino acids. Acidogenic bacteria then consume the sugars and acids to produce carbonic acids, carbon dioxide, ammonia, and other metabolic byproducts. Acetogenesis then produces acetic acid carbon dioxide, and some hydrogen. Methanogenic bacteria in turn produces methane and more carbon dioxide. Various other byproducts are produced depending on the conditions and input materials.

The production and accumulation of methane in this process presents some problems and opportunities. Methane has a significant global warming potential because of its ability to trap heat in the atmosphere, its durability in the atmosphere, and the large amount of it that is produced by human activities. For this reason, many countries require that methane levels be monitored at all landfill or biogas sites. The methane may be burned in a flare, or used for energy production.

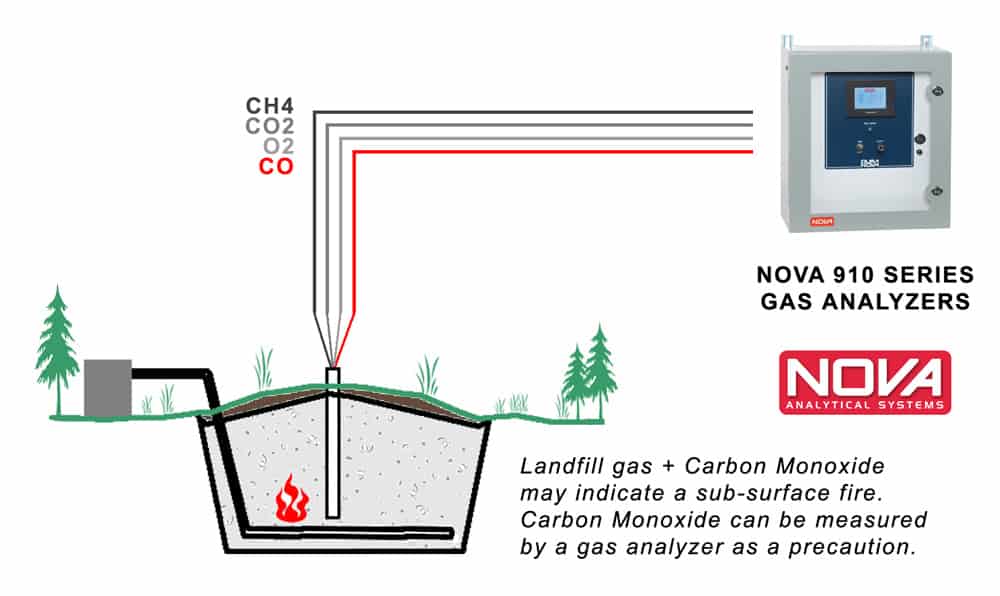

Methane may also pose a safety hazard at landfills if it is allowed to accumulate in areas of the site at levels above its Lower Explosive Limit. Methane pressure may also build up in the landfill under the cover. Even if an explosion does not result, sub-surface landfill fires may gradually burn over time and eventually develop into a destructive explosion event. If the liner under the landfill is breached, methane gas may also come into contact with groundwater, leading to groundwater contamination.

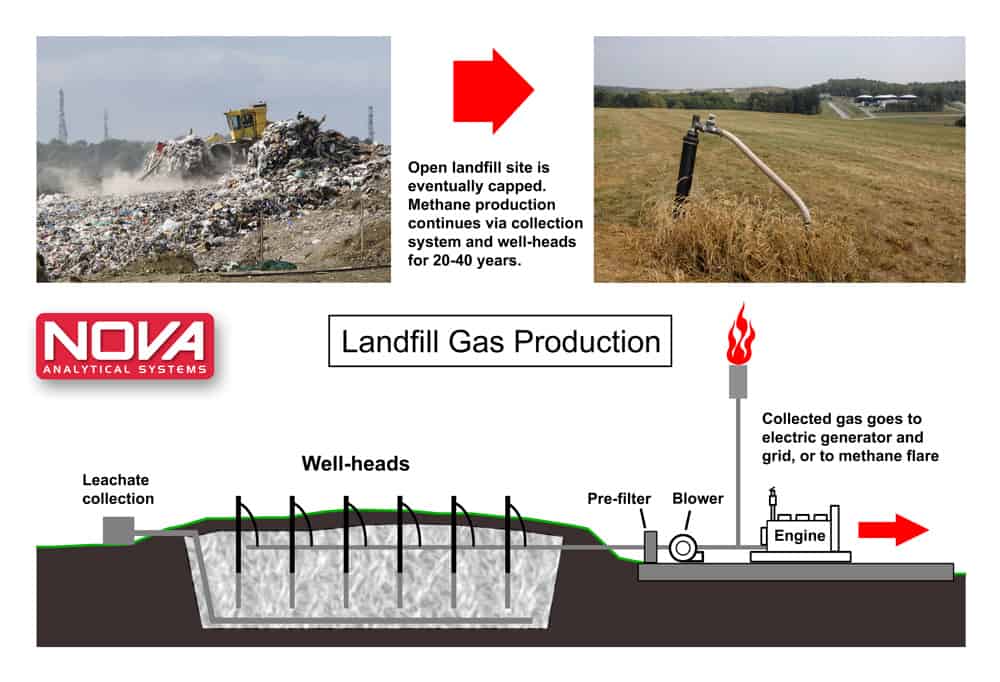

Methane also presents an energy opportunity. Because methane production in a landfill may last between 20-40 years, it is feasible to utilize it as an energy source to power stationary combustion engines which can in turn generate electricity. Biogas reactors will produce a reliable supply of useful methane as long as they are in operation. In some countries, a site may also be eligible for financial rewards for diverting methane from release into the environment.

Landfill and Biogas Gas Measurement

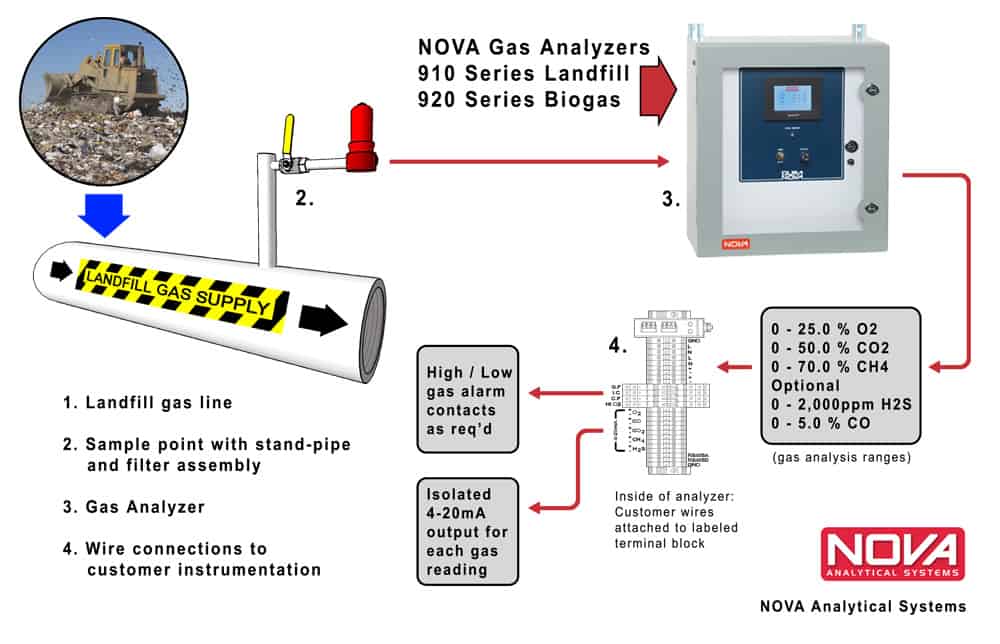

If the produced gas is being burned for power or for carbon credits, it is important to know in advance what the specific makeup of the gas is. It is also important to know this information on a permanent continuous basis. This is why an analyzer system is frequently required somewhere between the output of the gas supply line and the input of the receiving process.

The analyzer will provide a percent by volume reading of the methane (CH4) and carbon dioxide (CO2) levels. The oxygen (O2) readings on the analyzer may be useful in determining if there is an inbound air leak in the collection system. An analyzer equipped with carbon monoxide (CO) analysis may be useful for detecting a subsurface fire. Based on these results, adjustments or repairs can be made to restore safe conditions and optimize the heating value of the gas produced.

Extraction of the gas from a supply pipe is generally enabled via a stand pipe and filter assembly. This configuration provides a horizontal surface to allow some condensed water to run back down into the pipe instead of flowing toward the analyzer. The filter is intended to remove any dirt or particulate matter from the sample. Permanent sample tubing can then be installed between the extraction point and the gas analyzer.

These types of samples frequently have a high amount of water in the sample. It is best practice to remove bulk water before it enters the gas analyzer. In addition to the stand pipe arrangement, some sites have benefited from installing a cooler or a ‘drip-leg’ and drain arrangement just prior to the analyzer to further dry the sample gas.

Landfill and Biogas Analyzer Models

Relevant Nova gas analyzer systems include the following models:

- 910 Series Continuous Landfill Gas Analyzers

- Oxygen (O2) by electrochemical sensor

- Carbon Dioxide (CO2) by infra-red detector

- Methane (CH4) by infra-red detector

- Optional: Carbon Monoxide (CO) by infra-red detector*

- 920 Series Continuous Biogas Analyzers

- Oxygen (O2) by electrochemical sensor

- Carbon Dioxide (CO2) by infra-red detector

- Methane (CH4) by infra-red detector

- Optional: Hydrogen Sulfide (H2S) by electrochemical sensor

Nova equipment is frequently installed outdoors and in industrial environments. Our continuous analyzers are supplied in steel weather-proof cabinets. They are able to function in temperatures from -22 F to over 100 F with the appropriate weather package options. It is recommended to install analytical equipment inside a small shelter to prevent temperature swings caused by sun and wind exposure. It is also important to install freeze protection on all sample, vent, and drain lines.

Some sites require some type of hazardous area protection for the analyzer due to the installation location. Hazardous area kits may be installed on the cabinet to address some of these requirements. Even if the analyzer is mounted outside of a hazardous rated area, some sites have decided to purchase an optionally available in-cabinet leak detector which can de-power the analyzer in an alarm condition.

Biogas Applications

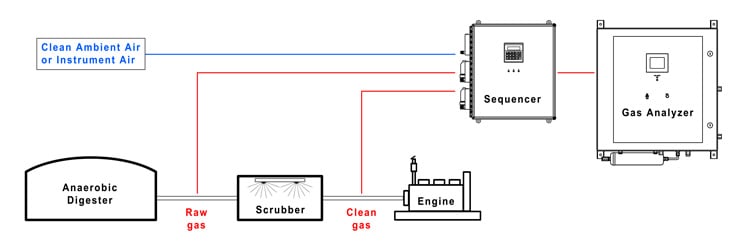

Some biogas sites have more than one anaerobic digester. One option to economically analyze multiple sample points is to purchase a sequencer, which can time-share a single analyzer over a few points.

- Nova Model 402 Autosequencer

An autosequencer may also be used to refresh a set of sensors after a cycle of all sample points. If the sample gas is aggressive, a final sample point consisting of clean fresh air may have value in purging and cleaning the sensors. Another use for this approach may be where there are multiple sample points with widely divergent readings. A brief fresh air purge can be inserted between the points.

Engines

The produced gas may be powering a stationary engine for electricity production. As shown the above diagram, a remediation system will be needed prior to the engine. The contaminant gases in the biogas will corrode the engine if left unchecked. A sequencer may be used to evaluate the efficiency of the scrubber by sampling the quality of the input and output gases.

The exhaust gas from the engine may also need to be measured for diagnostic reasons or emissions reporting. The gas products of engine combustion are much different from biogas. Therefore, a gas analyzer being used for biogas analysis cannot be used for engine exhaust analysis. The analyzed gases and ranges will be different.

For Flue Gas and Engine Exhaust Analysis, please see this page.

Ready for the next step? Please contact our Sales team for more information.

Or to provide us with more information about your application, please complete our Application Questionnaire and our Sales team will follow up with you promptly.