Flue Gas & Emissions Analyzers

NOVA 7200 Series Continous Flue Gas Analyzers

NOVA 5300FG Series Portable Flue Gas Analyzers

Flue Gas & Emission Analyzer Catalog

5300FG Portable Analyzer Info Page

Discussion

Furnaces, heaters, and boilers burn fuel in the presence of oxygen to produce heat. Achieving an intelligent balance of fuel and air will provide the most efficient combustion and highest cost savings.

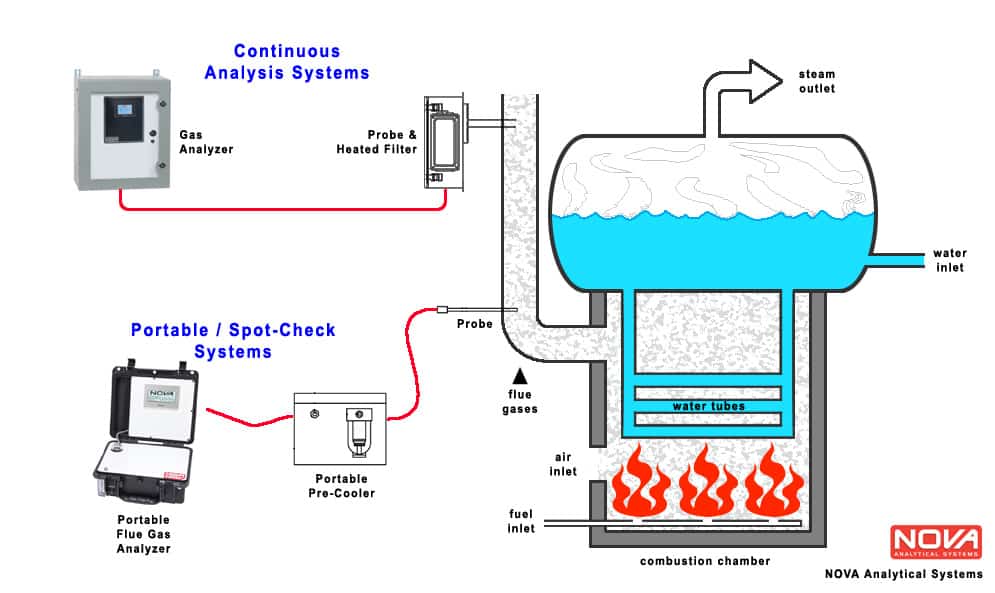

Measuring the exhaust gas is an excellent way to optimize fuel and air input. Nova manufactures continuous and portable analyzers for this purpose. A flue gas analyzer will enable you to measure the concentrations of various gases and adjust burners on a boiler to help achieve optimal combustion.

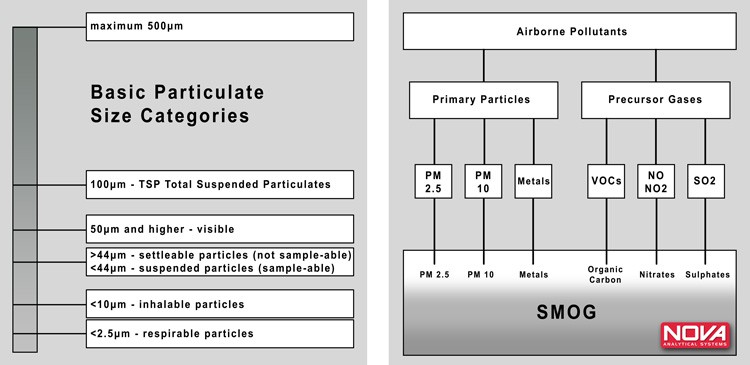

Efficient combustion also reduces emission of pollutants such as nitric oxide (NO), nitrogen dioxide (NO2), sulfur dioxide (SO2), and particulate matter. A combustion gas analyzer will help measure various gas pollutants in the exhaust for environmental reasons. One term that frequently arises in this application is ‘CEMS’.

CEM Systems

CEM Systems

CEMS is an acronym for Continuous Emissions Monitoring System. This term can technically apply to any instrument that is measuring some of the various constituents of exhaust gas on a continuous basis. However, the generally accepted use of ‘CEMS’ refers to an analyzer system that conforms to the methodologies and design features as outlined by a government environmental department such as the Environmental Protection Agency in the USA. Acceptable methods for sample conditioning, gas measurement, reporting of results, and other functions are established by the governing body and the resulting data will be accepted in emissions reports made to the government by the user.

In many countries, industrial facilities are required to report their emissions of various exhaust gases that are considered ‘criteria pollutants’. CEMS equipment can provide continuous analysis of many of these gases and can be used to report emissions. Particulate matter measurements may also be grouped with CEMS requirements. While not a gas itself, particulate matter does have environmental and health effects when it is small enough to be suspended in the atmosphere.

CEMS equipment usually tends to be quite expensive and may be an unsustainable cost for a facility. To satisfy the reporting requirements while minimizing equipment costs, some facilities install a lower-cost non-compliant analysis system at their emissions point. The analysis system is non-compliant in the sense that alternate conditioning and measurement methodologies not accepted by the governing agency are used in the gas analyzer. Once a year, the facility obtains the services of a mobile CEMS company to measure emissions using compliant equipment. The results are compared, and the relative accuracy of the installed non-compliant analyzer system is determined.

NOVA Capabilities

Nova has capability in the non-compliant CEMS category. Nova systems are accurate and durable, but they use some methodologies which may not be approved by some governmental agencies. These systems will require a Relative Accuracy Test Audit (RATA) once a year to evaluate the reporting accuracy of the combustion gas analyzer.

The NOVA 7200 Flue Gas Analyzer System uses the following measurement technologies:

- Oxygen by electrochemical sensor, range 0-25.0%

- Carbon Monoxide by electrochemical sensor, range 0-1,000 PPM

- Carbon Monoxide by infrared detector, range 0-2,000 PPM to 0-10.0%

- Carbon Dioxide by infrared detector, range 0-20.0%

- Nitric Oxide by electrochemical sensor, range 0-2,000 PPM

- Nitrogen Dioxide by electrochemical sensor, range 0-800 PPM

- Nitrogen Dioxide Calculation, based on Nitric Oxide measurement

- Sulfur Dioxide by infrared detector, range 0-2,000 PPM

- Stack Temperature by TypeK thermocouple, range 32F – 1800F or 0C – 1000C

Combinations of the above gas measurement options are usually also purchased with oxygen measurement. This allows the user to ‘normalize’ the other gas readings to oxygen. That is, they allow the other gas readings to be corrected by the customer to a reference oxygen content.

Our continuous flue gas analyzers are sturdy and weather-proof. They are able to function in temperatures from -22 F to over 100 F with the appropriate weather package options. They can also be modified with extra filtration devices for improved sample quality.

Nova analyzers use reliable high volume pumps for quick analysis times. In our stack gas analyzers, the detectors and sensors can reach 90% of reading in less than 20-30 seconds in most cases. (Sample line lengths will add to response time.)

Here are links to the on-line catalog:

- 7200 Continuous Flue Gas Analyzer System for Clean Gas

- 7240 Heated Probe & Filter System

Other features of the Nova Flue Gas Analyzer Systems:

- A variety of available cabinet packages allow for easy installation in different climates.

- Our continuous exhaust analyzers can be customized to include multiple sample extraction points.

- Hazardous area purge kits available by request.

- Most continuous flue gas analyzers can be supplied with optional Serial Output Package with a USB, RS-232, Ethernet, or RS-485 connection.

Click for Flue Gas Analyzer FAQs

Portable Flue Gas Analyzer Models

Nova has produced portable flue gas analyzers for more than 35 years. Technicians and facilities choose Nova Systems because they’re versatile, intuitive and easy-to-use, and durable.

Flue gas analysis using a Nova flue gas analyzer will enable you to measure the concentrations of pollutants present and adjust burners on a boiler for optimal combustion. Nova exhaust gas analyzers are useful for environmental control, for general boiler maintenance, and also as a tool for reducing fuel costs.

Links to Nova’s portable flue gas analyzers:

- 5300FG Series Portable Flue Gas Analyzers

- Portable thermo-electric style pre-cooler

- Portable ice-bath style pre-cooler

Additional Information

- Click for Flue Gas Analyzer FAQs

- If you are interested in flue gas analysis and need more information on these instruments, view our flue gas and exhaust analyzers here.

- For information on portable engine exhaust analysis, see this page.

- Ready for the next step? Please contact our Sales team for more information.

- Or to provide us with more information about your application, please complete our Application Questionnaire and our Sales team will follow up with you promptly.