Oxygen (O2) Analyzer

Oxygen Gas Analyzer Models

Our O2 sensor is of the long-life electrochemical “fuel cell” type. This sensor produces a small millivoltage output that is directly proportional to the oxygen detected. This output is then amplified and displayed on a digital readout meter and is also available as an output to your site data recorder. In some cases, we can offer PPM O2 ranges and paramagnetic O2 detectors, depending on the application.

Our analyzers can be supplied with a built-in sample pump or a pressure regulator to suit most applications. We offer portable oxygen analyzers as well as oxygen analyzers for hazardous conditions.

Several different cabinet styles are available, depending on the application.

We manufacture these oxygen gas analyzer models:

Oxygen Analysis Applications

Oxygen (O2) analysis is required in many of the industries and applications that are served by Nova Analytical Systems.

The intent of the analysis is sometimes to verify that there is low O2 content in a process. However, we can also provide O2 analyzers for combustion air O2 enrichment, flue gas analysis, oxygen deficiency analysis, and many more.

Ready for the next step? Please contact our Sales team for more information.

Or to provide us with more information about your application, please complete our Application Questionnaire and our Sales team will follow up with you promptly.

What Is an Oxygen Analyzer?

Oxygen analyzers measure the level of oxygen found in a given environment, improving both safety and efficiency in a wide range of industries. These important tools may either measure stack gas or inert gas.

Stack gas oxygen analyzers measure the amount of oxygen in exhaust gas after combustion. These measurements help to control the fuel-to-air ratio in the combustion process, which is crucial for improving boiler efficiency. In this scenario, the analyzer indicates whether there is too much or too little oxygen, either of which can cause excess energy loss during the combustion process.

Oxygen analyzers for inert gas measure the oxygen content in the inert gases that fill void spaces. Inert gas should always have a low oxygen content.

Oxygen analyzers are extremely important for various applications, including:

- Landfill gas, Biogas, Syngas. Though different, in order to work, each of these processes require an absence of oxygen. These processes produce combustible gases that can be used for energy production.

- Gas Plants, Transmission Lines, and Gathering Systems. The presence of oxygen in gas plants, gathering systems, and transmission lines can be dangerous, as it may indicate a leak in the infrastructure that can cause significant damage if not sealed. Oxygen analyzers help workers detect these problems more rapidly.

- Industrial Processes. In industries ranging from aerospace to electronics, the continual monitoring of oxygen levels helps companies maintain an efficient and safe manufacturing process, particularly when introducing nitrogen gas during production.

- Safety. In any situation where workers may be handling cryogenically liquefied gas or pressurized gas cylinders, it is vital to carefully monitor oxygen levels. Undetected leakage from these containers is highly dangerous, as it can rapidly deplete the oxygen levels in the surrounding area, putting employees at risk of injury or death.

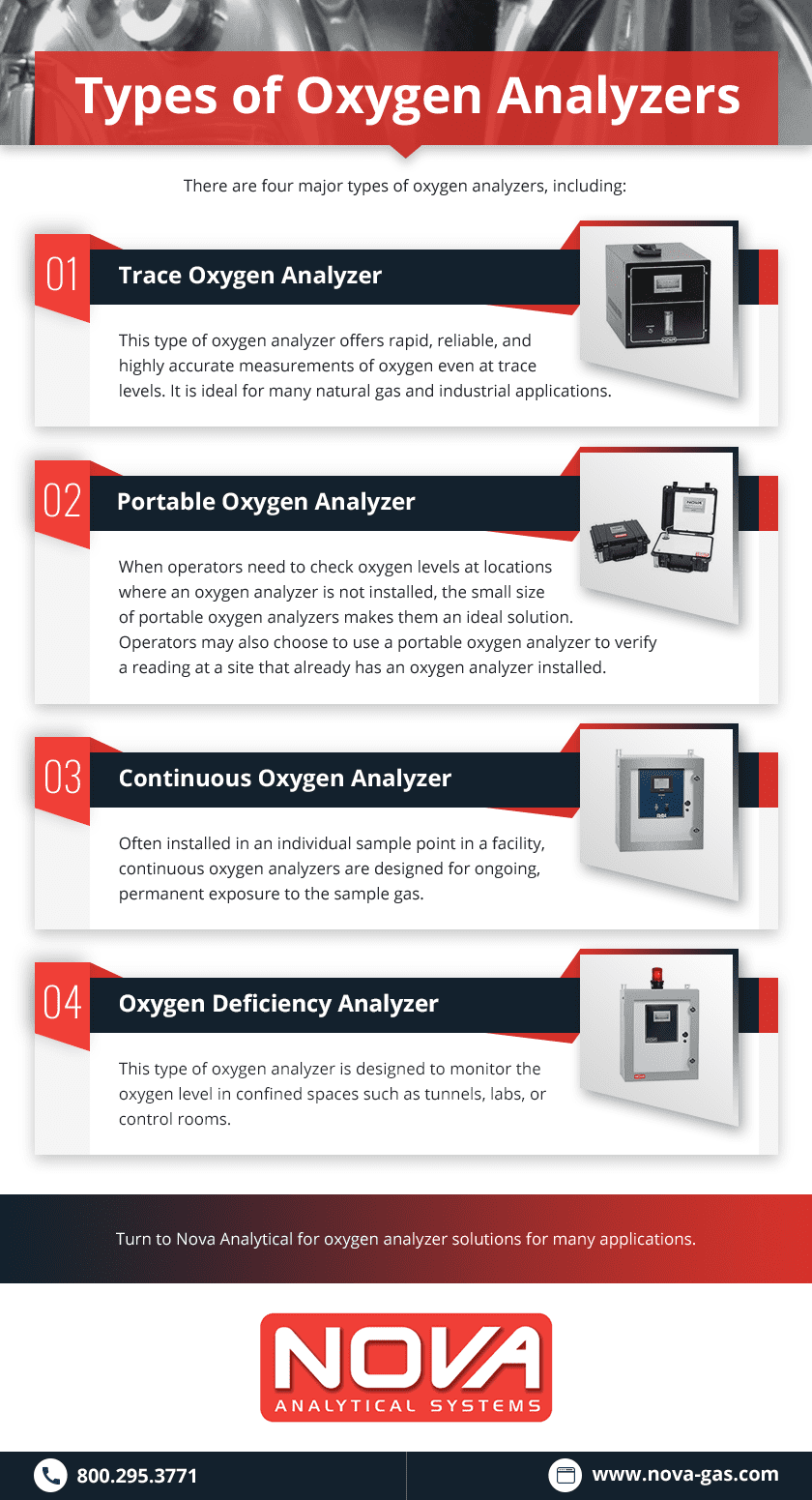

Types of Oxygen Analyzers

There are four major types of oxygen analyzers, including:

- Trace Oxygen Analyzer. This type of oxygen analyzer offers rapid, reliable, and highly accurate measurements of oxygen even at trace levels. It is ideal for many natural gas and industrial applications.

- Portable Oxygen Analyzer. When operators need to check oxygen levels at locations where an oxygen analyzer is not installed, the small size of portable oxygen analyzers makes them an ideal solution. Operators may also choose to use a portable oxygen analyzer to verify a reading at a site that already has an oxygen analyzer installed.

- Continuous Oxygen Analyzer. Often installed in an individual sample point in a facility, continuous oxygen analyzers are designed for ongoing, permanent exposure to the sample gas.

- Oxygen Deficiency Analyzer. This type of oxygen analyzer is designed to monitor the oxygen level in confined spaces such as tunnels, labs, or control rooms.

Oxygen Analysis Methods

There are several methods for analyzing oxygen. Three common types are electrochemical, paramagnetic, and in some cases thermal conductivity.

Electrochemical Oxygen Analyzer

Electrochemical oxygen analyzers are specifically designed to measure the percent concentration of oxygen within an external circuit. This type of analyzer contains working, counter, and reference electrodes contained within a gas-permeable membrane. When submerged in an electrolytic liquid, electrochemical oxygen analyzers detect and report oxygen levels based on the electrochemical reaction that occurs when the oxygen reaches the working electrode.

Trace Oxygen Analyzer

Some processes require measurement of very low levels of Oxygen in the part-per-million (ppm) range. Special types of electrochemical sensors can be used for this purpose. The basic operation of this sensor is similar to the percent Oxygen sensors mentioned above.

Paramagnetic Oxygen Analyzer

As oxygen molecules are attracted to strong magnetic fields, paramagnetic oxygen analyzers utilize a sampling system that contains nitrogen-filled spheres suspended within a magnetic field. Oxygen in the area will be attracted to the magnetic field, and the spheres will move proportionally to the oxygen concentration.

Thermal Conductivity Air Analyzer

These analyzers are made up of three different components: a sensing unit, a control unit, and a power supply. Thermal conductivity detectors may used in very specific applications in the power industry to monitor air content during maintenance work on hydrogen-cooled generators.

Oxygen Analyzers from Nova Analytical Systems

Oxygen analyzers are a critical tool that can keep workers safe, detect chemical leaks, and improve efficiency in a number of different industries. At Nova Analytical Systems, we offer a range of oxygen analyzer solutions for many applications. To learn more about our offerings, contact us or request a quote today.

What Is Oxygen?

Oxygen (O2) is the third-most abundant element by mass in the universe after hydrogen (H2) and helium (He). It is also the most abundant element by mass in the Earth’s crust.

For living organisms, uptake of O2 from the air is the essential purpose of breathing. Oxygen plays a critical role in cellular respiration, which is the process of converting food into energy. An adult human at rest inhales 1.8 to 2.4 grams of O2 per minute.

Approximately 100 million tonnes of O2 is extracted from the air annually for industrial purposes. The steel industry uses more than half of this amount. The process of smelting iron ore into steel requires high pressure injection of O2 into the molten steel. This removes impurities from the steel.

The remaining industrially produced O2 is used by the chemical, medical, metal-working, aerospace, and water treatment industries.