Controlled Atmosphere Analyzers

Controlled atmosphere facilities store food products in rooms that have tightly controlled conditions.

The temperature, humidity, and background gas of controlled atmosphere rooms may all be maintained at conditions that do not naturally occur in the ambient environment. This slows down the final ripening process of fruit that is physiologically mature but not completely ripe. For example, the Crispin (Mutsu) variety of apples can be stored in his state for 6-8 months in an atmosphere of 2.5% O2, 2.5 % CO2, balance N2, at 0°C.

Failure to maintain the optimum storage conditions can lead to spoiling of the fruit or storage disorders such as poor flavor development, water loss, low sugar content, high acidity, etc.

Other food production applications may also require specific atmospheres to produce or store their products.

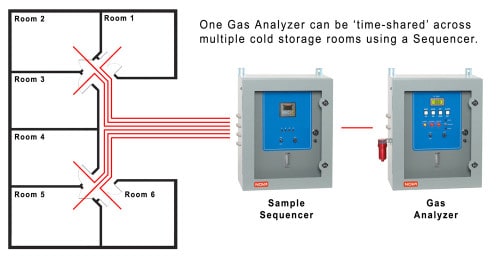

Various Nova analyzers are well-suited for monitoring controlled storage rooms. Depending on the requirements of the facility, a simple portable spot-check analyzer, or an automated multi-point system may be used.

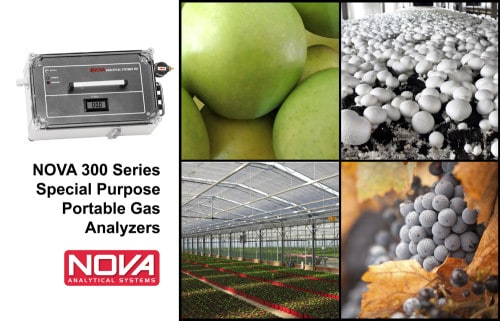

Some controlled atmosphere applications only require spot-check style measurements instead of permanent-continuous measurement. Several Nova products from the 300 Series Portable Gas Analyzers can be used to verify the content of a specific storage room.

Click this product page for analyzers that may be used for controlled atmosphere applications.

If you are interested in controlled atmosphere analysis and need more information on these instruments, you can request a quote here.