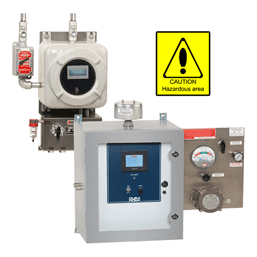

Hazardous Area Analyzers

Nova manufactures some gas analyzers in cabinets that are suitable for Hazardous Areas such as Class 1 Divisions 1 & 2 and Zone 1 or 2.

Explosion-Proof Cabinets

For Class 1 Division 1 applications, we frequently offer a NEMA 7 ex-proof cabinet. The cabinet itself is a heavy cast aluminum box with mounting feet. There may be a threaded solid metal cover or there may be a windowed cover through which the controls are magnetically operated. The gas entry and exit points of the analyzer will have flame / flash arrestors and the wire entries must be protected with a properly-installed EYS seal.

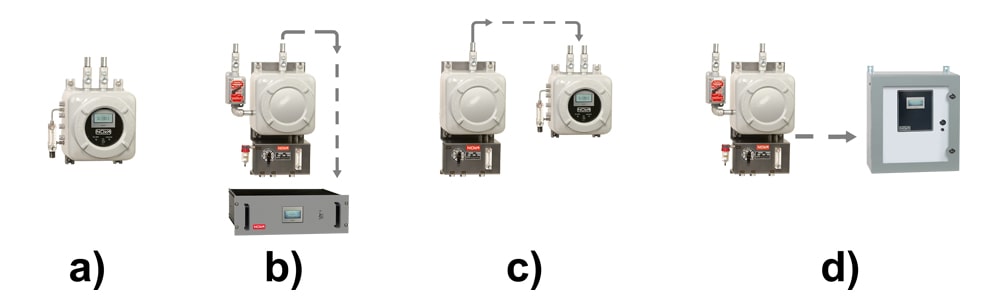

There are a few ways of configuring these analyzers as shown below.

a) Explosion-proof cabinet with detector and local display

b) Explosion-proof detector cabinet with rack-mount control cabinet

c) Explosion-proof detector cabinet with explosion-proof control cabinet

d) Explosion-proof detector cabinet with NEMA 4 wall-mount control cabinet

With a) and c), the complete system may be installed in the hazardous area. With b) and d), only the detector cabinet is installed in the hazardous area. The control cabinets are suitable for non-hazardous areas only and are typically installed in a control room nearby.

Due to size constraints of the ex-proof cabinets we use, these analyzers are usually suitable for analysis of only one gas in a sample that is clean and dry. Our most popular models are:

Model 410N7MC Oxygen Analyzer

Model 420N7MC Carbon Dioxide Analyzer

Model 430N7MC Hydrogen Analyzer

Model 436N7MC Air / CO2 / H2 Analyzer for Power Generators

Model 480N7MC Carbon Monoxide Analyzer

Here are some other potential choices.

Purged Cabinets

Another way of meeting hazardous area requirements is to install a positive pressure purge system on the analyzer cabinet as shown below. This might be a suitable alternative to an explosion proof cabinet when more than one gas is to be analyzed, or the sample gas requires additional sample conditioning prior to analysis. These situations require a larger wall-mount cabinet that is not inherently suitable for hazardous areas.

A purge system uses a supply of instrument air or inert gas such as nitrogen to perform two phases of explosion protection.

1. An initial purge process removes any potentially explosive atmospheres from the enclosure.

2. After initial purge, sufficient compressed air or inert gas is supplied to maintain a constant positive pressure inside the analyzer cabinet. The cabinet will likely have outgoing leaks. The purge system monitors pressure in the cabinet and ensures that it remains above the surrounding ambient pressure to prevent ingress of potentially explosive atmospheres.

A positive pressure system is suitable for integration with equipment that is not intended for use in hazardous areas. The positive pressure system allows the equipment be installed and operated in the hazardous area.

These systems require a supply of instrument air or inert gas to function.

In most cases, any gas analyzer that can be built into our standard NEMA 4 cabinet can have a positive pressure purge system installed onto it.

If you have a requirement for a gas analyzer that must be installed in a hazardous area, we may be able to assist you.

Ready for the next step? Please contact our Sales team for more information.

Or to provide us with more information about your application, please complete our Application Questionnaire and our Sales team will follow up with you promptly.